Descripción

El nuevo Side View trae la tecnología de rayos X XR75 y un bajo costo total de propiedad a la inspección de paquetes rígidos. Las aplicaciones incluyen botellas de PET, bolsas verticales, cartones verticales y empaques asépticos. El Side View es una solución sin contacto con un espacio compacto de 2 m. Se monta sobre su línea de producción existente, lo que elimina las transferencias de productos y los atascos. Una nueva adición a la línea de rendimiento XR75, el sistema ofrece una detección de contaminantes inigualable junto con un bajo consumo de energía que proporciona un retorno de la inversión superior.

orte

Especificaciones de rayos X de vista lateral

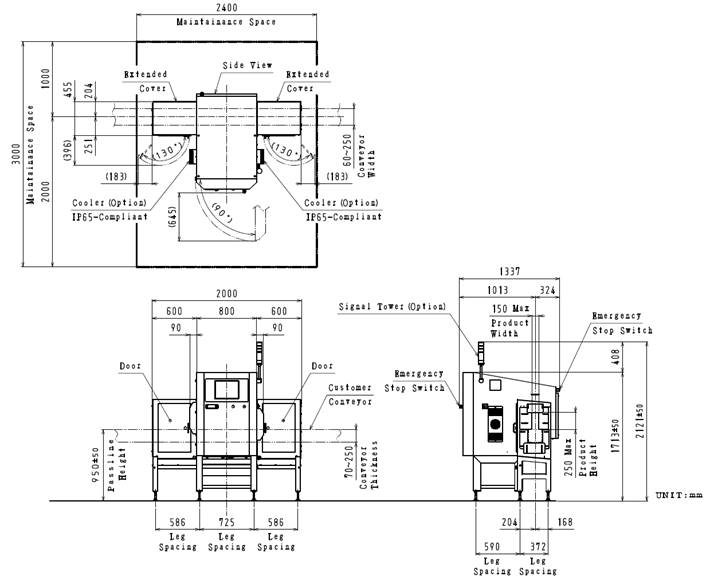

- La solución se monta sobre el transportador del cliente, sin puntos de transferencia ni cortinas

- Ancho máximo del transportador del cliente: 250 mm

- Altura máxima del transportador del cliente: 250 mm

- Ancho máximo del producto: 150 mm

- Altura máxima del producto: 260 mm

- Velocidades de la banda: 10 a 120 m/min

- Lavado: IP65 (KXE7514BVELE), IP40 (KXE7514BWELE)

- Longitud total: 2000 mm

- Tiempo de rechazo: pulsos del codificador

Benefits

Recognizing the short-and-long-term requirements of today’s processors and manufacturers, our engineers designed the XR75 Advanced Long Life Technology to provide heightened sensitivity at reduced energy levels. Because of this, cost of ownership is significantly lowered and life cycles are extended.

Additionally, the XR75 incorporates new advanced long-life technology for critical system components. The long life x-ray tube/generator and detector have been designed for years of maintenance free service. Overall, the XR75 x-ray inspection system can reduce lifetime operating costs by more than 20 percent compared to conventional models, making food inspection more affordable.

Best in Class

- Detection – as small as 0.5mm

- Flexibility – HD Imaging standard

- Reliability resulting in minimal to zero downtime

- Efficiency in parts, support and documentation

World Class Reliability

Anritsu has been manufacturing inspection systems for over 50 years and has always strived to become more accurate, stable and reliable. Over 10,000 x-ray inspection system installations in food and pharmaceutical facilities worldwide are a testament to the reliability of our equipment and our passion to deliver the most accurate inspection possible. Our industry leading technology and decades of expertise show in every design, and is fully backed by our service team for years of reliable service in your facility.

Long-Term Flexibility

The Anritsu XR75 x-ray platform includes all software inspection tools and capabilities as standard. Each product setup can be configured to your exact product using variable speed conveyors, variable power x-ray source, HACCP support and Ethernet for connection to Anritsu’s QuiCCA data collection software. The goal is to provide our users a long-term, flexible solution for any new applications that may require x-ray inspection.

Ease of Use Increases Efficiencies

Quick installation and system training are made possible by having a common user interface that is easy-to-use and easy-to-understand. The XR75 user interface is the same as the Anritsu SSV checkweighers or M5/M6 metal detectors minimizing training time. Operators can easily create new products and adjust existing settings, eliminating the need for factory support.

Ease of Maintenance

Reliability in the design minimizes the need for maintenance, but when required, a full suite of system diagnostics, unique error and alarm codes offers quick maintenance and minimizes any downtime. On screen prompts guide corrective actions to, in many instances, reduce the need to contact maintenance.

Features

When it comes to accuracy and reliability in food x-ray inspection, the XR75 series is the top in its class. It efficiently performs food inspection for all products at lower energy levels, resulting in a reduced true cost of ownership.

The precision-engineered, highly-sensitive Side View X-Ray system is the latest in the advanced XR75 series of inspection solutions. It sets a new standard for improving product quality and safety, exceeding the needs of today’s demanding food processing industry. In addition to contaminant detection, it can also identify packaging defects and fill level.

| Detection Capabilities |

|

| Metal |

0.6-0.8mm |

| Wire |

0.5-0.7mm x 2mm long |

| Glass |

2.0-3.0mm |

| Stone (red meat) |

2.0-3.0mm |

| Virtual Weighing |

Yes |

| Missing Item, Fill Level |

Yes |

| Technology |

|

| HD Imaging STANDARD |

|

| System Features |

|

| ALL – Advanced Long Life Technology |

|

| Variable X-Ray Power by Menu |

|

| Low x-ray power: 150W |

|

| Integrated Cabinet Cooling System |

|

| Secondary cooler optional for high temperature environments |

|

| Solid State Drive and Embedded Software |

|

| Sealed, Non-Circulating Tube Cooling System |

|

| 15″ Touch Screen HMI |

|

| Sanitary Features |

|

| Mounts over customer’s conveyor – no moving parts |

|

| Angled External Surfaces |